#three stage plant manufacturer

Explore tagged Tumblr posts

Text

As the industry develops, the need for aggregate rises, bringing in a period of rapid growth for the sand sector. Sand Making Machine, as the core equipment of the sand making assembly line, has more variations to better adapt to the evolution due to each user’s various production demands.

#m-Sand Making Making#100 tph Stone Crusher Plant#two stage plant manufacturer#three stage plant manufacturer#four stage plant manufacturer

0 notes

Text

Shining a Light on Tradition: The Cultural Impact of Solar Power in Remote Communities

Today, we are entering a world bathed in sunlight, not just literally, but figuratively. This is the reality for many remote and indigenous communities around the globe who are embracing solar energy. But the impact goes beyond simply flipping a switch. Solar adoption is quietly weaving itself into the very fabric of these communities, transforming not just lifestyles and economies, but also cultural practices and traditions.

Flickering Hope: Lighting Up Remote Lives

Having access to dependable energy has long been a pipe dream for many rural communities. Diesel generators, often the only option, are expensive, noisy, and environmentally harmful. Enter solar power, a clean and sustainable solution that harnesses the abundant sunshine these regions naturally receive. Ground-mounted solar installations or even floating solar panels on lakes and reservoirs are changing the game. Homes that were once shrouded in darkness after sunset are now illuminated, allowing children to study longer and families to gather under a brighter sky. This newfound access to electricity is a fundamental shift, empowering communities and fostering a sense of progress.

Empowering Hands: Building a Brighter Future

The benefits extend beyond basic lighting. Solar panel installation projects are creating new opportunities in these communities. Locals are being trained in solar technology, fostering a sense of ownership and creating jobs within their own communities. In addition to bringing in much-needed revenue, this gives people and communities the power to take control of their energy requirements. Imagine a young lady from a far-off village training to be a proficient solar specialist, her expertise lighting not only houses but also a way forward for a better future.

Weaving Sunlight into Tradition

The cultural impact of solar adoption is a story waiting to be told. In some communities, solar power is being used to support traditional practices. Solar-powered refrigerators are keeping food fresh, ensuring the preservation of indigenous diets and cultural foodways. Solar-powered water pumps are bringing clean water closer to homes, aligning with traditional reverence for water and the natural world. This integration of solar technology with cultural practices creates a beautiful synergy, demonstrating that progress doesn't have to come at the cost of tradition.

Challenges and the Road Ahead

Of course, challenges remain. Installing solar panels can be expensive initially, and in distant locations, there may not be as much technical know-how available for upkeep. However, innovative financing models and partnerships with organizations like GREW are helping bridge these gaps.

Lighting the Way Forward

For decades, remote communities relied on noisy, polluting diesel generators, limiting power and shrouding nights in darkness. This hampered education, livelihoods, and even food preservation. But a new dawn is breaking. Solar power, clean and abundant, is changing the game. Ground-mounted installations or floating solar panels on lakes are bringing reliable light to homes once bathed in flickering candlelight. This shift from diesel to sunshine-powered electricity lays the foundation for a brighter future, where tradition and progress can thrive together.

GREW is a prime example of a company that is dedicated to both community development and sustainability. Their three-stage fully backward integrated manufacturing ensures quality and affordability, making solar power more accessible to remote communities. Their commitment to providing clean energy solutions to those in need is demonstrated by their solar module plant in Kathua, India. GREW’s ground-mounted solar and floating solar panels projects are changing lives, and their module manufacturing facility guarantees the high standards required for effective implementation. By working together, companies like GREW and forward-thinking communities can ensure that the light of solar power continues to illuminate not just homes, but also cultural traditions and a brighter future for generations to come.

For more: Shining a Light on Tradition: The Cultural Impact of Solar Power in Remote Communities

#ground-mounted solar#floating solar panels#solar panel installation#module manufacturing facility#three-stage fully backward integrated manufacturing#solar module plant in kathua

0 notes

Text

adventures in aerospace

So I recently started working at Large Aircraft Manufacturer. (LAM) The plant I work at employs 30,000 people. The company as a whole employs 170,000. Usually you only hear about LAM when something goes wrong. But no matter how bumbling it seems from the outside, it's way worse on the inside.

Three months after my first day, I have been "graduated" from "training." In reality, I'm still completely worthless on the floor: the training center has given me a paltry subset of the production certificates I need to actually to do my assigned job. A commonly cited statistic at LAM is that a hundred men a day are retiring, each one representing decades of experience, walking out the door, forever. The training center is in the unenviable position of managing a generational replacement, and have resorted to shoveling heaps of zoomers through as fast as possible. (As one of the few people with a visible hairline and who is not wearing a Roblox graphic tee; I am frequently mistaken for an instructor, and asked where the bathroom is, what time the next class starts, etc)

In theory, the training center knows what shop I'm assigned to, and can simply assign me all the required classes. In practice, they do the absolute minimum amount of training in a desperate attempt to relive the crowding in their handful of computer labs and tell graduates to pick up their certs later.

Of course, the irresistible force of the schedule meets the immovable object of the FAA. If you don't have the required production certificate to perform a particular job, you don't touch the airplane. Full stop, end of story.

And so the curtain opens on the stage. It reveals a single senior mechanic, supervising a mechanic who finally received all the certs and is being qualified on this particular job, surrounded by another three trainees. Trainees are less than nothing, absolute scum. At best we can fetch and carry. Mostly we are expected to stay out of the way. And the senior mechanic is only senior in title. He is one of six assembler-installers who is certified to actually work on the plane, out of twenty people on the crew, and spends every day with a permanent audience. He is 23 years old.

("Mechanic"? If you think the jargon at your job is bad, try joining a company that's a century old. Assembler-installers are universally referred to as "mechanics", despite doing work that's nothing like what a car mechanic does, and who are generally paid far worse than FAA certified A&P mechanics. Mechanics are the 11 bravos of LAM, grunts, the single largest category of worker. The tip of the spear. Hooah!)

Large Aircraft Manufacturer is in a dilly of a pickle. All of its existing airframe designs are hilariously antiquated. It tried designing a brand new plane from a clean sheet, and lost billions of dollars to a decade-long integration hell. After that, to save money, it tried just tacking bigger engines on an older design without changing anything else, and the stupid things plowed into the ground in an excruciatingly public manner.

LAM is now trying a middle road. It is upgrading one of its designs that is merely middle aged, rather than ancient, and with proven, de-risked components built in-house, rather than scattering them to subcontractors across the world. And it's still blowing past deadlines and burning billions of dollars LAM really doesn't have to spare.

This is the program I've been assigned to.

Advanced Midbody - Carbon Wing has taken the bold step of just tacking on carbon fiber wings to a conventional aluminum fuselage. Shockingly, AMCW is now stuck in lightning strike testing, due to that troublesome join between conductive aluminum and conductive...ish carbon fiber. But LAM, confident as ever, or perhaps driven by complaints of its customers, has announced that full rate production will begin just next year. Thus the tide of newhires. According to the schedule, we're supposed to jerk from one wingset a month to one wingset a week. That's not going to happen, but, oh well, orders from above move down at the speed of thought, while reality only slowly trickles upwards.

"120 inch pounds? Really?"

I startle upright. I have observed one hundred pi bracket installs, and I will observe a hundred more before I can touch aircraft structure. This is the first disagreement I've witnessed. A more advanced trainee is questioning the torque spec on a fastener. It is not an entirely foolish question-- most sleeve bolts we use are in the 40 in-pounds range. Doubling it that is unusual. I cough the dust off my unused vocal cords and venture an opinion.

"Well hey I could look it up? I guess"

The lead mechanic glances at me, surprised that I'm still awake, then looks away. Excuse enough for me!

I unfold myself from the stool I've been sitting on for the last four hours then hobble over to the nearest Shared Production Workstation.

We do not get Ikea-style step by step instructions on how to put together the airplane. Like any company that's been around for long enough, LAM is a tangled wad of scar tissue, ancient responses to forgotten trauma. If you state a dimension twice, in two different places, then it is possible for an update to only change one of those dimensions, thereby making the engineering drawing ambiguous. Something real bad must have happened in the past as a result of that, so now an ironclad rule is that critical information is only stated once, in one place, a single source of truth.

As a result, the installation plan can be a little... vague. Step 040 might be something like "DRILL HOLE TO SIZE AND TORQUE FASTENERS TO SPEC". What hole size? What torque spec?

Well, they tell you. Eventually.

(Image from public Google search)

You are given an engineering drawing, and are expected to figure out how things go together yourself. (Or, more realistically, are told how it's done by coworkers) Step by step instructions aren't done because then dozens of illustrations would have to be updated with every change instead of just one, and drawings are updated surprisingly frequently.

Fasteners are denoted by a big plus sign, with a three letter fastener code on the left and the diameter on the right, like so: "XNJ + 8"

To get the actual part number, we go to the fastener callout table:

(Note the use of a trade name in the table above. There is nothing a mechanic loves more than a good trademark. Permanent straight shank fasteners are always called HI-LOKs™. It's not a cable tie, it's a Panduit™. It's not a wedgelock, it's a Cleco™. Hey man, pass me that offset drill. What, you mean a Zephyr™? Where'd the LAMlube™ go? This also means you have to learn the names of everything twice, one name on the installation plan, and one name it's referred to in conversation.)

We find XNJ on that table, and fill in the diameter: BACB30FM8A. Now we look up the spec table for that fastener:

The eagle eyed among you might note that there is no "diameter: 8" on that table. As a LAM mechanic, you are expected to simply know that "diameter" is measured in 32nds of an inch, which simplifies down to 1/4.

(LAM preserves many old-school skills like fraction reduction and memorizing decimal equivalents like this, like flies caught in amber. Not least is the universal use of Imperial units. Many American manufacturers have been browbeaten into adding parenthetical conversions. Not LAM! Any risk at all of a mechanic seeing a second number and using it by accident is too great, and anyway, it violates SSOT. Lengths are in inches and feet, weights are in pounds, volume is in gallons and if you don't like it then you can go eat shit!)

After 10 minutes of following references, I arrive at that table, print it off, highlight the correct row, and hand it off to my senior mechanic.

"Great, thanks."

Gratified that I have enhanced shareholder value, I sit back down, and immediately fall asleep. Another day living the dream.

(next post in this series)

417 notes

·

View notes

Text

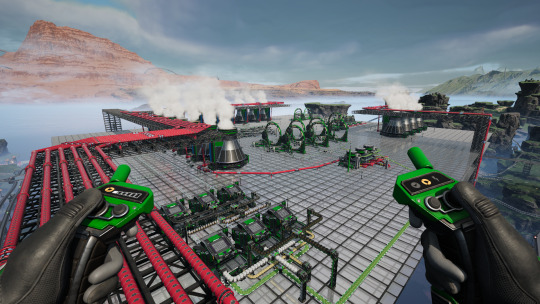

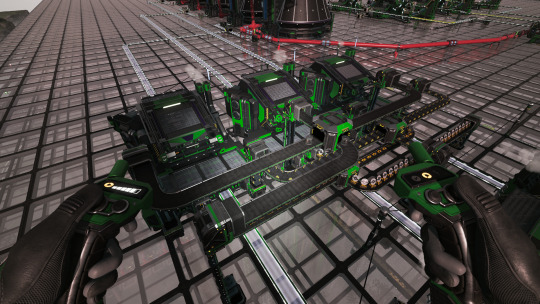

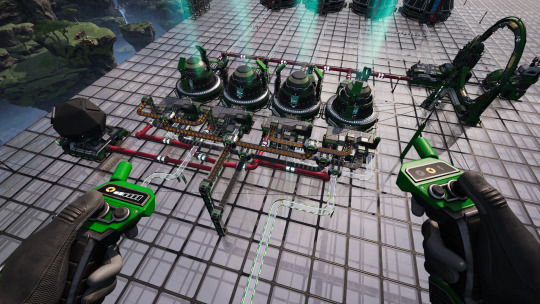

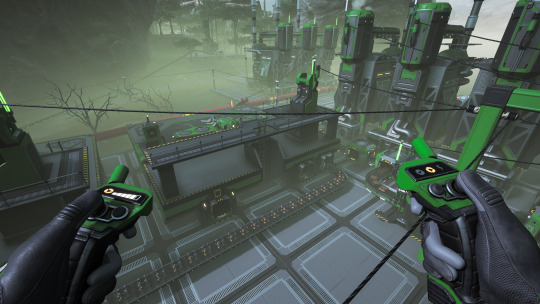

Satisfactory: The Full Ficsonium-Chain Nuclear Power Plant

Okay.

So.

I did it.

The thing I love doing most in Satisfactory is creating giant power plants that give me way more power than I need so I don't have to worry about my overhead while making other things. It's the thing that really captured and hooked me into a loyal player.

In the 1.0 release, they added a way to fully engage your uranium resources and make plutonium power without unsinkable waste product, by adding a third step called Ficsonium.

And so the gauntlet was thrown down.

Starting out, making this all work looked impossible. But slowly, I whittled away at it, optimized it, until I had a workable plan. And now that I've built it, I'm going to subject you all to the write-up.

93.75 Uranium, 93.75 Sulfur, 56.25 Silica, and 281.25 Quickwire goes into 3 Manufacturers (overclocked to 125%) to make 75 Encased Uranium Cells (using the Infused Uranium Cell alternate recipe).

(All material numbers are in parts-per-minute, by the way, in case that confuses anybody.)

Those E.U. Cells go straight into 3 more Manufacturers (again, overclocked to 125%, and the Cell outputs/inputs are 1:1), along with 7.5 Electromagnetic Control Rods, 2.25 Crystal Oscillators, and 7.5 Rotors to make 2.25 Uranium Fuel Rods (using the Uranium Fuel Unit alternate recipe).

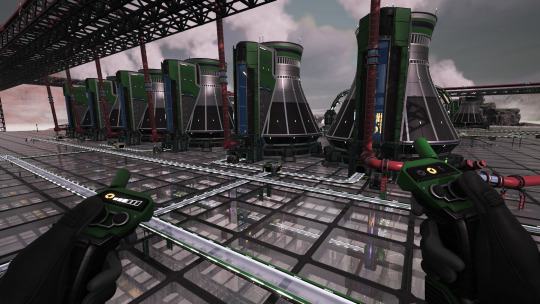

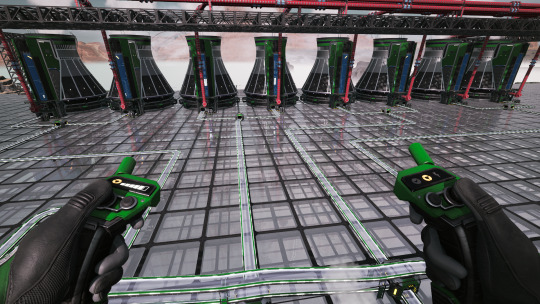

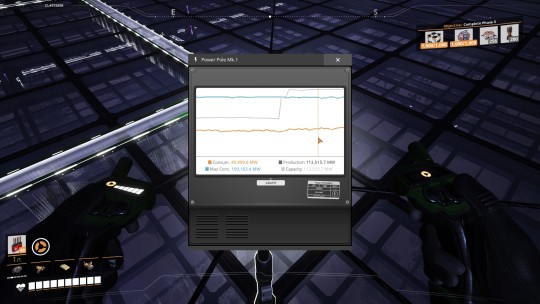

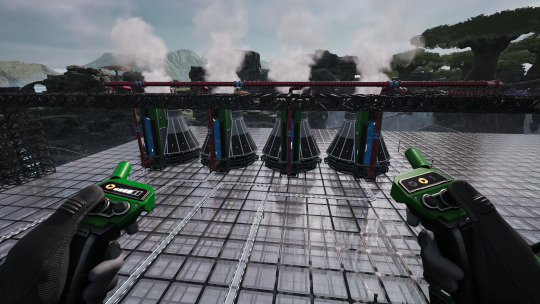

The Uranium Fuel Rods are fed into 6 Nuclear Power Plants (each overclocked to 187.5%, so the equivalent of 11.25 power plants). Each fuel rod Manufacturer splits its outputs to two of the power plants. The power plants are fed with 450 cubic meters of water each from the framework above (except for the nearest one, which is also taking water byproduct from the next stage). Together, the uranium power plants produce 28,125 MW of electrical power and 112.5 Uranium Waste.

The Uranium Waste is quickly conveyed beneath the floor over to three Blenders (overclocked to 150%), along with another 112.5 raw Uranium, 67.5 Nitric Acid, and 112.5 Sulfuric Acid, to make 450 Non-Fissile Uranium (using the Fertile Uranium alternate recipe). This also produces 180 water byproduct, which is fed back into the first uranium power plant.

Each Blender feeds into its own row of 2 Particle Accelerators, for a total of 6. (No overclocking here, for once!) The Non-Fissile Uranium is mixed with 60 total Aluminum Casings to produce 60 Encased Plutonium Cells (using the Instant Plutonium Cell alternate recipe).

The Encased Plutonium Cells are fed into 4 Manufacturers (overclocked to 200% - and we're back), along with 36 Steel Beams, 12 Electromagnetic Control Rods, and 20 Heat Sinks, to make a whole whopping 2 Plutonium Fuel Rods!

(Everything up to this point is considered "Stage One" of the overall nuclear power plant. At this juncture, I left the remaining power plants unconnected and simply destroyed the Plutonium Fuel Rods in the AWESOME Sink while I took a break and worked on other parts with the electrical power the uranium plants alone were giving me. Everything after this is considered "Stage Two," the even more complicated part.)

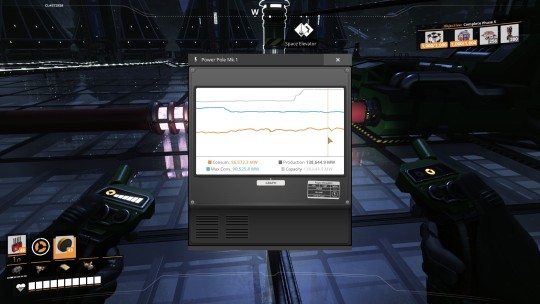

Once the rest of the chain was ready, I connected the Plutonium Fuel Rod Manufacturer outputs to 8 more nuclear power plants (overclocked to 250%, effectively 20 power plants!), 2 for each line. Each plant gets 600 water from overhead as well. This alone gives me another 50,000 MW of power!

...But it also produces 20 Plutonium Waste, which until 1.0 was completely indestructible and had to be stored away in a dedicated dump indefinitely.

(Sure, people have done the math. With enough space, you can buy yourself literal months of in-game uptime before your dump fills up with waste and the power plants become inoperable, in exchange for writing off that part of the map. But why give yourself any such hassle at all if you don't have to? Sustainability is a part of efficiency!)

The Plutonium Waste is brought over to 2 Particle Accelerators and combined with 20 Singularity Cells and 400 Dark Matter Residue (neither of which are cheap!) to make 20 Ficsonium.

The Ficsonium, 20 Electromagnetic Control Rods (again! so many!), 400 Ficsite Trigons (!!!), and 200 Excited Photonic Matter (dirt simple, actually - phew!) are fed into 4 Quantum Encoders to make 10 Ficsonium Fuel Rods. This also produces 200 Dark Matter Residue as a byproduct, which I put into a Particle Accelerator to make Dark Matter Crystals that I just toss into an AWESOME Sink.

(If you're smart, you could just loop the byproduct here back into the previous step and cut that input in half, but... I just could not be bothered this time. I wanted this plant fully operational as soon as possible.)

And finally, the Ficsonium Fuel Rods are sent directly from the Quantum Encoders to 4 Nuclear Power Plants (overclocked to 250% again, effectively 10 power plants) and mixed with 600 overhead water each to produce another 25,000 MW of power and absolutely zero waste or byproduct.

For a grand total of... 103,125 MW!

(And that's before adding bonus power from Alien Power Augmenters later!)

This was a massive build that took up the entire swamp region of the map (because to hell with the swamp, all my homies hate the swamp and their eldritch-moving alpha spiders). There's an interim layer of the platform for "spaghetti," or conveying the materials to where they need to go, and then just about everything needed for this process was made from scratch from within the swamp or close-by-ish.

With one exception: I drone'd in Pressure Conversion Cubes that I was making elsewhere for the Nuclear Pasta that's required for the Singularity Cells. Having to make Radio Control Units and Fused Modular Frames from scratch on top of everything else just would've tipped this over the breaking point for me personally.

And that's that. Probably the biggest power plant I'll ever want to make in Satisfactory, at least on my own in single-player. I've taken the gauntlet and thrown it back. And now I have more than enough power to finish the rest of the game.

Thanks for reading! I worked way too hard on this whole project.

(Also, for those who may be looking at this flow and thinking, "Holy crap, you'll need hundreds of Reanimated SAM and thus thousands of SAM!" - here's a pro tip: Somersloops. Overclock the Constructors making your Reanimated SAM to max and then throw in 1 Somersloop. Instantly improves the recipe from 4:1 to 2:1. I'm dead certain this was an intended part of SAM balancing, because holy crap there's just not enough of it on the map otherwise.)

#satisfactory#satisfactory game#satisfactory screenshot#nuclear power#nuclear energy#factory post-mortem write-up#please come look I worked so hard on this#shouting into the void

21 notes

·

View notes

Text

[WESKER'S REPORT / EXTRA]

A very intriguing incident . . . A series of bizarre murder cases have been occurring at a wintry village in the rural Caucasus region of Russia. The villagers there are clamoring about a legendary monster, "Almas", having risen from the dead . . . This wretched state of affairs effortlessly reminds me of those initial bizarre cases in Raccoon Forest. Three kilometers away from that village there stands an antiquated chemical plant built during the Soviet era, ownership of which, according to our investigation, currently lies with a prestigious European aristocrat. Foreign capital appears to have been invested five years ago for undertaking major underground development. Geological surveys reveal the presence of solid bedrock, perfect for constructing a certain kind of facility. It would seem as though we've solved the puzzle. Umbrella has shamelessly clung to life in the five years since Raccoon's annihilation. Despite facing accusations of leaking the virus along with their stock prices crashing, they unfurled the trial with a campaign claiming it all to be a U.S. Government conspiracy, which has been successful in stalling for time until their eventual death sentence. Fortunate for Umbrella, then, that they had been colluding with the government from the beginning. A state naturally has secrets of its own that can be dusted off, and their survival tactic was to sell those off piece by piece to the court and mass media in order to foment public skepticism. Something akin to madness lurks more or less within every person and organization, even among nations. The most deranged in that incident, however, was none other than Umbrella. A simple-minded Umbrella is exhibiting signs of a revival. B.O.W.s are starting to overrun war zones. They are supplying those B.O.W.s as weapons. We've also received reports that, beneath the surface, Umbrella have arranged a framework for manufacturing bioweapons while operating ships to transport them. The time has come. They tinker with the t-Virus, cultivate mutant organisms, then sell them. Moreover, even if they were to yield certain results, with their capacity for imagination incapable of treating the virus as anything more than a vector for bioweapon production, they will only end up exposing their defects at some other point in time. The "Philosopher's Stone" is destined for the hands of a truly worthy alchemist. The unworthy must be taken off the stage. This place is sure to be the site of Umbrella's end.

15 notes

·

View notes

Text

Updated: December 23, 2024

Reworked Character #9: Tequila

POTENTIAL TRIGGER WARNING: Viewer discretion is advised due to references to death, torture, suicide, child abuse, cannibalism, crime, alcoholism, and divorce.

Real name: Sermeg Bracquemond-Kagamihara (he legally changed his name to Sosuke N. Kanikoja)

Alias: Maestro of a Thousand Skirmishes

Occupation: Lieutenant General of the S.P.A.R.R.O.W.S., Brigadier General of the Regular Army, Army Chief of Staff for the Rebel Army (formerly), and mercenary for the Theophylaktos Union (formerly)

Retirement plans: Open a florist shop, become a philanthropist dedicated to supporting child welfare and war veterans, and establish a company that designs and manufactures affordable, electric vehicles

Special skills: Coordinating covert missions and training programs for new recruits, proficiency in tactical planning and the operation of heavy machinery, mastery of disguise, and rescuing hostages

Esper abilities: He can teleport short distances, allowing him to instantly vanish and reappear in locations just out of his direct line of sight. He boasts flexibility rivalling that of an octopus due to his extreme hypermobility, and agility nearly identical to that of a cheetah. Furthermore, his senses are incredibly acute, featuring eyesight as keen as an eagle's, hearing as sensitive as a bat's, a sense of smell as discerning as an elephant's, and touch sensitivity as refined as a star-nosed mole's.

Whenever he suffers a debilitating three-minute headache, accompanied by a brief, cryptic glimpse of the future, it signals his sensitivity to celestial events, planetary alignments, and cosmic anomalies that will significantly impact Earth. Furthermore, he possesses a passive ability to sense environmental changes, allowing him to predict weather patterns, earthquakes, and other meteorological and geological events within his immediate region. This precognitive awareness is limited to a fifteen-minute timeframe before the event occurs.

He has two black half-orbs, one in the centre of each palm, which possess a red-violet lustre and serve four distinct purposes. Firstly, they enable him to absorb memories and knowledge from the recently deceased and bodies in various stages of decomposition. Secondly, he can conjure balls of radiant blue fire, precisely directing them at his enemies. Thirdly, by tapping into the energy of shadows and nighttime darkness, he can forge obsidian-handled scythes with glowing bluish-white blades that inflict severe burns even with the slightest graze against skin. Once he's finished wielding the scythes, the orbs disintegrate them, reducing their physical forms to nothing but a pile of ash. Lastly, by touching someone's heart, he can absorb their emotions to heal minor wounds and partially mend major ones. However, this leaves the individual emotionally numb, stripping them of their emotional depth forever.

Hobbies: Playing underground poker games, watching demolition derby events, tinkering with and customising his own vehicles, cultivating deadly plants and sweet-smelling flowers, and engaging in friendly fire incidents during covert missions

Likes: Gourmet grilling, the innocent curiosity of children, enjoying a drink after a long battle, the symbolism and cultural significance of flowers, and exploring exotic destinations and natural wonders

Dislikes: Captivity, troublemakers, bureaucratic red tape, being stuck in tight spaces (especially during an escape), and witnessing comrades and children being exploited and oppressed or caught in situations of gratuitous violence

Favourite food: Tequila (tequila sunrise is his most favourite) and his own gourmet grilled food

Sexuality: Panromantic graysexual

Gender: Male

Age: 50 (in 2022), 56 (in 2028), 58 (in 2030), 60 (in 2032), 62 (in 2034), 69 (in 2041), 71 (in 2043), 72 (in 2044), and 75 (in 2047)

Blood type: A-

Weight: 109 lbs. (49 kg)

Design: He’s a 5 ft (152.4 cm) Canadian-Guatemalan ectomorph of French and Japanese descent with a lean, semi-lanky build, subtle softness around the midsection, and a weak yet surprisingly stocky musculature. He has sloping shoulders, beige skin (it was pale ivory during his younger years), and a small black mole on the right side of his chin. His face shows noticeable signs of aging with forehead lines, frown lines, tear troughs, and nasolabial folds. He has a missing second premolar on his lower jaw and heterochromia eyes: his right eye is a medium sky blue and his left eye is a deep cyan. Tequila sports a brownish-black spiky crew cut dyed a light auburn, which is paired with sideburns, semi-bushy eyebrows, and a slightly dishevelled five o'clock shadow. On his right outer thigh, he has a tattoo depicting a seven-horned Lamb of God, its legs bound, holding an olive branch in its mouth. The lamb is set against a backdrop of a gilded Chi Rho symbol (☧), which is encircled by a radiant, flaming aureola.

He bears numerous battle scars from past encounters, including: half of his upper back being heavily burned; a series of jagged cuts on his left arm caused by shrapnel; a deep, curved scar on his temple; a thin, horizontal knife scar on his chin; a slight cut on his left cheek from a bullet that flew past him; and a bullet wound below the right side of his diaphragm. Tequila also has a series of deep stab wounds on his right shoulder and right lumbar region, a severed tendon (flexor carpi ulnaris) in his left forearm, and a partially cut left thumb.

After being experimented on, his body underwent significant transformations: his muscles have a coppery hue with bronze streaks, his bones are gilded and steel-hard, his fingers and toes are tipped with razor-sharp claws and talons, and his eyes glow a deep crimson in the nighttime. His back is covered with blotchy, necrotized flesh that bears a resemblance to the starry night appearance of the Avatar of Evil's skin.

His military gear consists of brass-plated goggles with yellow-orange lenses, a navy blue bandana mask, a bone white tank top with a slight rip just above the left hip, and greenish-black gloves. He wears army cargo pants in a camouflage pattern featuring cerulean, lavender grey, and Cambridge blue, which are tucked into spike-soled liver brown combat boots. His pants have two crudely stitched patches: a triangular brownish-red one on the right knee and a rectangular steel blue one on the middle of his left outer thigh. Tequila wears a metal dog tag necklace with his name, navy blue elbow and knee pads, a bronze-buckled leather belt, a sheath for his combat knife, and a drop leg holster for a handgun with a silencer. A Prussian blue waist pack is secured to the back of his belt, containing a bronze-finished flask filled with his tequila cocktail of choice for the day.

He wears a linden green flight jacket, often left unzipped, featuring a brown wolf-fur lining, a metallic silver zipper, and gilded epaulets. The jacket has four pockets and boasts the S.P.A.R.R.O.W.S. logo emblazoned on the back. His jacket has a concealed compartment on the left side, secured with a strap, holding the latest rolled-up newspaper. Additionally, he wears a reseda chartreuse armband on his left sleeve, adorned with the Regular Army insignia. He typically wears a blue-green Lightweight Helmet (LWH), but occasionally opts for a gold-edged wedge cap of linden green seal fur instead. Slung over his right shoulder, he carries the scoped bolt-action rifle he retained after leaving the Theophylaktos Union.

Over his tank top, he dons a Soldier Plate Carrier System (SPCS) with a cerulean, lavender grey, and Cambridge blue camouflage pattern, which carries around his walkie-talkie and ammo for other firearms. He wears three dark grey bandoliers: one draped over his right shoulder holds flashbang grenades, another over his left shoulder holds smoke bombs, and a third wraps around his waist above his belt, holding ammunition for his handgun. Tequila carries around a steel blue load-bearing backpack that contains camping equipment, tactical explosives, portable ammo boxes, a canteen full of water, a brown bear fur blanket, a grappling hook, and a disguise kit that adapts to the specific requirements of each mission. It also contains a Gatling shot, practical tools like mechanic and lockpicking sets, and a photo album filled with Polaroid pictures.

The pockets of his flight jacket carry around a metallic blue-green lighter, the key to his motorcycle, noise-cancelling earplugs, and a hundred-eyed cowrie shell, a gift from Gimlet. Tequila treasures a collection of cherished photographs, which are carefully stored in the pockets of his flight jacket. One shows him with his ex-wife, Margaret, and their late son, Thomas, enjoying a spring day at a Quebec park. Another captures a moment with his former team in front of the old Joint Military Operations Headquarters in Andrew Town, where a teenage Gimlet stands proudly beside him, beaming with a thumbs up. Other cherished photos include: a Swiss brassy ringlet on a yellow mountain flower; Red Eye playfully placing an orange tabby cat on a sleeping Donald Morden in his former office; a mountain hike with Clark; and a triumphant pose with Marco, Tarma, Gimlet, and Red Eye standing before a destroyed Tani Oh.

He has a stash of cigars and a half-empty pack of cigarettes tucked away in the right pocket of his army cargo pants, while his left pocket is occupied by a burgundy instant camera, a digital recorder, a silver engagement ring featuring a princess cut diamond, and a golden wedding band. Ever since he encountered a Swiss brassy ringlet during a hike through the rocky meadows of the European Alps, he fell in love with them and proudly displays a pin depicting one on the left side of his flight jacket. He wears two distinctive necklaces: a black cord with a teardrop-shaped nazar charm and a gold chain holding a pendant of the Immaculate Heart of Mary impaled by a longsword.

His custom-made motorcycle is a glaucous BMW R75, adorned with forest green cheetah spots outlined in sandy beige. The motorcycle comes with a sidecar, which serves as storage for extra supplies and his load-bearing backpack. The sidecar features an intriguing design element: a Swiss brassy ringlet on the antler of an elk skull, proudly displayed on its side. The sidecar is outfitted with a greenish-black rocket turret, while two rotating miniguns are mounted on either side of the front wheel of his motorcycle.

Character summary: He's a cunning, wise, rebellious, and skeptical individual with a strong aversion to being bossed around unjustly. He has a tendency to bluff and revels in the raw power and adrenaline rush that comes with high-intensity situations, which makes him feel alive. He has a strong sense of camaraderie with those he considers comrades and close friends, going to great lengths to ensure their happiness and safety. Tequila is especially devoted to Marco, Tarma, Red Eye, Gimlet, Clark, Eri, and Fio, holding their well-being in the highest regard due to the deep affection he feels for them. Depending on the situation, he can be very blunt, believing that people need to quickly learn that the truth is often a hard pill to swallow. Whenever his patience is running thin or he deems it necessary, he isn't afraid to speak his mind, though his words can be abrasive and unsettling.

Despite his perpetual weary expression, he’s a fundamentally kind-hearted and morally upright leader. Tequila is a tough-as-nails and hypervigilant individual that has a tendency to engage in occasional reckless behaviour. He has a cynical, pessimistic outlook on life, which he occasionally masks through social drinking, reading the newspaper or immersing himself in his hobbies. As an introvert with an exceptionally high intellect, he finds it challenging to connect with others. He has a deep-seated compassion and strong protective instincts towards children who are vulnerable to abuse and exploitation. Tequila views it as a moral obligation to safeguard them from harm and foster a secure environment that allows them to thrive.

He battles alcoholism, stemming from guilt over not helping his sister during her darkest moments, the accidental loss of his first love, and the devastating death of his son. Despite these painful memories, he's actively seeking help and working to improve his mental well-being. Remarkably, he's also supporting friends struggling with similar alcoholism issues, using his personal experience to help others. When drunk, he exhibits clumsiness, boisterousness, sorrowfulness, physical aggression, and increased insulting behaviour (far more than usual). Additionally, he's even more likely to make awkward attempts to flirt with anyone who catches his eye.

He's particularly self-conscious about his height and extremely hates being teased about it. When someone teases him about his height, he tends to respond in one of two ways: either with sarcasm, pretending to find the joke amusing, or by lashing out with rude insults, often targeting their appearance-related insecurities. When he's feeling scared or furious towards someone who has visibly angered him, he has a habit of jumping on their back, which may follow up with an attack. Tequila has zero tolerance for cowardice and incompetence, viewing them as lame excuses for people to avoid putting in effort and failing to contribute meaningfully to their roles in society. He dislikes people who are overly pesky or slimy, individuals with a bratty and entitled attitude, unnecessary trouble, political corruption, and duplicity.

As a devout Catholic who also believes in the evil eye, he abhors war and can't help but feel a pang of sympathy for new military recruits, knowing their innocent worldview is likely to be shattered. Nevertheless, he recognizes that everyone has their own reasons for enlisting and refrains from criticising their choices. Although he once devoutly followed the Avatar of Evil and still respects the principles the deity represents, he now sees them as a primarily malevolent force, akin to the Devil, with a destructive influence on human life. He wants to believe in the singular, all-powerful deity of his Catholic faith, but he's aware that this conviction is challenged by the confirmed existence of multiple deities and the possibility of attaining godhood.

He’s devoted in being a loyal friend and mentor to all, and he takes pride in being regarded as a living legend, thanks to his distinguished reputation as the Regular Army's top covert agent. He becomes vengeful when he encounters people who have been unreasonably hurt or when he feels betrayed and devastated after losing something he deeply cares about. He’ll only betray someone or a cause if he senses that they’re crossing into morally reprehensible territory.

He becomes visibly upset when he learns of suicide cases or attempts. In such situations, he promptly offers comfort and support to those affected, providing valuable guidance and a listening ear. He lives with sleep paralysis, atypical depression, and mild borderline personality disorder and PTSD. When seeking solitude and contemplation or grappling with doubts about his faith, he withdraws to a secluded natural haven, wrapping himself in a fluffy blanket and using earplugs to shut out the world. Whenever he encounters a pair of glowing red eyes, a creeping sense of unease settles in, leaving him questioning his grip on reality.

He harbours a deep-seated hatred towards his former friend, General Morden, stemming from his subsequent betrayal when Morden's megalomaniacal desire for world domination consumed him. He perceives Margaret as promiscuous and attention-seeking, disapproving of her flirtatious behaviour as a means to cope with loneliness. Despite their divorce, he remains deeply invested in her well-being and still harbours lingering romantic feelings for her. As a result, he has been gradually rekindling their romantic connection, alleviating her loneliness and showing her she’s still loved and valued. Through this process, they are also working together to heal from the profound loss of their son. He's a good friend of Hyakutaro, and they often hang out together after missions, talking about how crazy their day was, sharing vacation plans, and discussing a wide range of random topics.

He has a strong affinity for Vasser, whom he sees as a surrogate son, striving to educate and guide him on the right path. However, he often finds himself disappointed by Vasser's ill-tempered bully attitude, his excessive thirst for blood and action, and his tendencies to slack off, cause mischief, and make unwanted advances towards women. He also feels deeply disappointed when Vasser disregards his advice and falls short of the standards he envisioned, which were modelled after his deceased son Thomas—an exceptionally well-behaved child with a keen mind and an eagerness to learn. He becomes extremely frustrated with Vasser's antics and consistently reprimands him for his poor behaviour, urging him to take responsibility for his mistakes and learn from them. He's consumed by guilt, feeling that despite his best efforts, he's failed as a father and wonders if he could have done more to prevent Vasser's bad behaviour.

Backstory: Sermeg Bracquemond-Kagamihara was born on December 23, 1972 in Chichicastenango, Guatemala. His biological parents were Kafkasi Bracquemond, a French-Canadian construction worker from Trois-Rivières, Quebec, Canada, and Tsukiko Kagamihara, a Japanese-Canadian entrepreneur who owned an open-air market selling homemade Japanese craft goods. He had an adoptive sister who was six years older than him named Ximena, who had been abandoned by her alcoholic father.

As expected, he had inherited Tuatha Dé Danann DNA from his parents, which became noticeable when he frequently mentioned seeing a pair of glowing red eyes watching him. Sermeg's parents had also noticed that his intelligence grew at rapid speeds, which they greatly encouraged. Between the ages of 1 and 4, he read numerous books on various subjects, including mathematics, engineering, sociology, psychology, architecture, ancient history, geography, political science, and world religions. By the age of 5, he had taught himself to speak Japanese, Korean, French, Italian, Spanish, Portuguese, Romanian, Russian, and German, and learned about their respective cultures.

Before Sermeg's 7th birthday, his father was assassinated by a hitman in retaliation for killing the right-hand man of a prominent Québécois organised crime family near Montreal. Prior to his death, Kafkasi had fled with his wife, Tsukiko, to Guatemala. The crime family, seeking revenge and viewing Tsukiko and her children as potential assets, had planned to force them into hard labour and prostitution. Out of fear, Tsukiko made the tough decision to put Sermeg and Ximena up for adoption, hoping they would be safe. Shortly after, Tsukiko vanished mysteriously, leaving behind only speculation that she had fallen prey to the Québécois crime family's sinister activities.

They were adopted by an organ harvester named Tecuani, who took pity on them after learning about the fate of their parents. Despite his illicit profession, Tecuani went out of his way to ensure that Sermeg and Ximena were well-fed and properly educated. He even taught them essential survival skills for navigating the dangers of the streets, giving them a better chance at thriving in a challenging world. However, their time together was short-lived, as Tecuani was promptly arrested after one of his employees reported him to the police for operating an illegal organ harvesting business.

As a result, Sermeg and Ximena were placed into the foster care system, where they experienced a tumultuous journey through four different foster families. The first family was neglectful and struggled with addiction, the second was intimidated by Sermeg's abnormal intelligence, and the third, although kind and lenient, harboured an uncle who posed a sexual threat to Ximena.

Tragically, their last foster family was a source of immense pain and suffering. The foster father, a business executive named Clifford, was controlling and abusive, lashing out physically and emotionally, especially when Sermeg dared to stand up for himself. The foster mother, a psychiatrist named Magdalena, failed to provide a safe and nurturing environment, neglecting their needs and belittling them with hurtful words that preyed on their insecurities. During this period, he struggled to connect with his sister, their vastly different intellectual abilities driving a wedge between them. Additionally, he would occasionally get into altercations with children from more stable homes at the local park, struggling to manage his frustration. Ximena, who had always been dear to Magdalena, struggled with depression, PTSD, and body dysmorphia, which ultimately led to her eventual suicide when Sermeg was just 12 years old.

At age 15, Sermeg joined a newly formed cartel that promised him refuge and financial assistance in exchange for killing and cannibalising his foster parents. Initially hesitant due to his disgust at the idea of consuming his abusers, he was motivated by the prospect of exacting revenge. He followed through on the cartel's demands, completing his initiation and rapidly rising through the ranks thanks to his street smarts. He played a key role in gathering valuable intelligence for the cartel's boss and devising strategic plans for financial management and tactical attacks.

To cope with his emotional pain and seek excitement, he turned to drinking various tequila cocktails, eventually leading to an alcohol addiction and a particular fondness for tequila sunrise. His struggles with addiction led to him being dubbed "Tequila" by those around him, a nickname he unexpectedly embraced as part of his identity and later adopted as his codename for military operations.

The circumstances of his departure from the cartel are unclear, but rumours suggest that the cartel was either absorbed into or annihilated by a relatively obscure cult-like guerrilla group from Venezuela known as the Theophylaktos Union. However, it's confirmed that he did join the Theophylaktos Union at age 19, becoming a skilled mercenary and spy for the organisation. He confesses that during his time in the Theophylaktos Union, he had a boyfriend, but their relationship was tragically cut short. His partner was inadvertently killed in a friendly fire incident, a devastating consequence of his own actions while infiltrating the Argentinian police to gather resources. This was also when he began exploring mechanics and constructed his first custom-made motorcycle.

At the age of 21, during a raid on a Brazilian town, he encountered a frightened child clinging to her dead mother and her severely injured younger brother. Initially, he callously shot her, believing her to be an obstacle to fulfilling the Dark Lord's supposedly twisted desires. Yet, upon reflection, he questioned his actions and his allegiance to the Theophylaktos Union, ultimately realising that this path was not for him. He subsequently retired from the group, assumed the alias Sosuke N. Kanikoja for his protection, relocated to Trois-Rivières, Quebec, Canada, and sought rehabilitation to address his escalating alcohol addiction. He also converted to Catholicism in search of new purpose and direction in life. To support himself, he took on two part-time jobs: working as a grill cook at a bar and grill, and serving as a cashier at a local flower shop.

During his lunch break at the bar and grill where he worked, he met Hyakutaro, fresh from completing a gruelling mission for the Regular Army. They quickly formed a strong bond after sharing their personal struggles and aspirations. Hyakutaro encouraged him to join the Regular Army, hoping it would give him a sense of direction and purpose. Inspired by their conversation, he made a drastic career change, leaving his Quebec-based jobs behind to enlist in the Regular Army at 25.

He then went on to specialise in high-stakes hostage rescue missions. He also developed expertise in camouflage, secret identities, and intelligence gathering, earning recognition as the Regular Army's top covert agent. His exceptional leadership skills, tactical planning, and recruitment abilities further propelled him to the rank of Brigadier General. However, his experiences soon exposed him to the harsh realities of war and corruption, witnessing the brutal deaths of many friends and comrades. These traumatic events would haunt him, fuelling recurring nightmares and night terrors.

Four years after joining the Regular Army and Intelligence Agency, he was among the first to be transferred to the newly established S.P.A.R.R.O.W.S. special forces unit, becoming one of its founding members, alongside Red Eye. He met Margaret Southwood shortly after the S.P.A.R.R.O.W.S. was established, encountering her at the Combat Academy section of the Intelligence Division. He immediately fell in love with her and decided to ask her out on a few dates, which blossomed into a romance. As their relationship grew, they eventually got married and had a single child together, naming him Thomas. Tragically, their marriage was short-lived after their five-year-old son was killed by a drunk driver. As they both struggled to cope with their grief, Margaret turned to promiscuity and Tequila turned to drinking as a means of distraction. Unfortunately, these coping mechanisms created an insurmountable rift, leading to their divorce.

At age 39, after exiting a pub and heading back to a nearby Regular Army base on his motorcycle, he noticed a malnourished teenage boy lying in an alleyway with a bruised and bloodied face. He took great pity on the boy and promptly aided him, noticing the boy's eerie silence and uncanny resemblance to Thomas. He decided to head back to the base later and instead brought the boy to a restaurant, buying him lunch. After a couple of minutes of trying to encourage the boy to speak, he finally introduced himself as Vasser Gutenschiff-Wolstenholme and shared his story of taking to the streets to escape his abusive father, Kanan. Moved by Vasser's situation and seeing it as a duty to protect children from harm, he vowed to enact vengeance. With the assistance of Vasser, he ambushed Kanan by breaking into his house, then adopted Vasser through the Regular Army's orphan program.

A couple of years after Vasser's adoption, he met Morden unexpectedly while serving with the North American Garrison, which was assisting the European Garrison and Middle Eastern Garrison in thwarting an Oceania military organisation's attempt to spark a full-scale nuclear war. Following the successful completion of this mission, they forged a bond over drinks and shared stories of their challenging childhoods. Morden also expressed his admiration for Tequila's courage in his espionage work and leadership abilities within the North American Garrison.

He would eventually become a revered mentor and friend to many, including Clark, Red Eye, Tarma, and Marco. Notably, he encouraged Vasser to join the Peregrine Falcons Squad, but this guidance had an unexpected consequence: Vasser began to reveal a more attention-seeking and bloodthirsty side, indulging in troublesome, slothful, and lecherous tendencies that led to several issues. In addition to rescuing hostages, he consistently went above and beyond to save children who were in imminent danger or at risk of harm, making their safety a top priority regardless of the mission. One mission that remains etched in his memory is when he rescued a group of children being trafficked and sold on the black market, while his team simultaneously took down the criminals responsible for this heinous crime.

He played a key role in the Arms Deal Barrage and defeating the remnants of the Serapion Fellowship. He was primarily responsible for leading rescue missions for prisoners of war, gathering and providing crucial intelligence on enemy positions, and leading his team in combat operations. He's the primary reason the event bears the name “Barrage”. He orchestrated an artillery bombardment on the fortress housing a critical power facility and a massive space rocket, significantly weakening the Serapion Fellowship's defences. However, the mission would uncover a shocking truth: the Regular Army was secretly involved in an illegal arms deal with the Serapion Fellowship. This revelation was shared by him, alongside Gimlet and Red Eye, with Sagan, Logan, Hyakutaro, Morden, and Allen O'Neil. This moment opened his eyes to the Regular Army's secret corruption, but he remained silent, fearing that speaking out would make him a target for swift assassination as a whistleblower.

Three years after the Central Park bombing, Morden secretly approached him at a bar and convinced him to defect. Believing it was a good opportunity, he quietly resigned from the Regular Army and S.P.A.R.R.O.W.S. to join the Rebel Army. Tequila soon learned that Sagan and Logan had been secretly working as double agents for General Morden after the Central Park bombing. Despite his displeasure, he vowed to keep Sagan and Logan's secret, promising not to reveal their duplicity to Gimlet. However, he added a warning: if they ever harmed him, he has the right to expose their deceit to Gimlet.

He excelled as a top-notch spy, often disguising himself as a Rebel soldier in a woodland military uniform for land troops. He rose to become Morden's right-hand man, serving as the Army's Chief of Staff. However, after nearing one year of service, he discovered General Morden's true intentions and how he had fully succumbed to his megalomaniacal desires. Horrified, he promptly left the Rebel Army and defected back to the Regular Army, warning them about the impending rise of the Rebel Army. However, despite his inside knowledge, they were unable to prepare in time as General Morden successfully launched a surprise attack, overpowering them and rapidly consolidating his global dictatorship.

During the Great Morden War, he aided Marco in leading the governmental resistance against the Rebel Army. Although he held a higher military rank than Marco, he allowed Marco to take the initiative, recognizing his great potential to become a truly charismatic leader. After being ambushed by Morden and his forces, he was brutally tortured and forcibly killed in front of Marco and Tarma. However, Morden promised to bring him back in a greater form, sending his deceased body to Doctor Amadeus. Doctor Amadeus successfully revived Tequila, but as a semi-clone of Hyakutaro, significantly altering his existence. Unlike Gimlet and Red Eye, he was the sole recipient of a small infusion of godly DNA.

#writerscorner#creative writing#writing#iron eclipse au#death tw#abuse tw#cannibalism tw#alcoholism tw#metal slug#snk#gaming community#rework#redesign#name#alias#job#skills#abilities#power#hobby#likes and dislikes#food#sexuality#gender#age#blood type#weight#personality#backstory#tequila

10 notes

·

View notes

Text

Report from Superintendent Henderson to the Commissioner requesting assistance in rounding up and arresting illicit distillers and bootleggers on Indian Reservations.

Record Group 75: Records of the Bureau of Indian AffairsSeries: Subject Numeric Correspondence Files

Cherokee, N.C., May 10, 1919. Honorable Cato Sells, Commissioner of Indian Affairs, Washington, D.C. My dear Mr. Sells, A condition has arisen on the Cherokee Reservation in regard to the manufacture and sale of whiskey which I deem it my duty to advise you of and ask for assistance in breaking it up. Prior to a few months ago I had very little trouble along this line and with the aid of the county and stage officials was able to cope with the situation, but since whiskey has arisen to the enormous price of $20 a gallon there has been an epidemic of "moonshining" and bootleging in the mountain country and I regret to say that the Cherokee Reservation is no exception. Two large lumbering industries have sprung up adjoining and near the reservation that have brought several hundred whites among whom there are a number of undesirable citizens. About one month ago an officer of the Internal Revenue Department aided by some of my employees raided a plant on the reservation located quite near the home of an Indian and destroyed it but failed to get the operators. On May 2, the sheriff of Swain County and I destroyed a plant near the house of a squaw-man but failed to get the operators, and on the 12th, inst. a party of my employees and I captured a plant in operation and the three operators two of whom are mixed blood Indians. I am confident that a number of other such plants are being operated from time to time on and near the reservation by parties so adroit and cunning in the art of "moonshining" and bootlegging making it well nigh impossible for those of us who are known to them to have a reasonable degree of success in hunting them down. In view of these facts, the thought has come to me that you might consider detailing at least two of Mr. Larson's force to aid the civil authorities and me in clearing the Cherokee Reservation of these undesirables who are debauching the Indians and nullifying to a degree the efforts we are putting forth on the reservation for good. They should come among the people in disguise prepared to stay a month or more before making any arrests. Sincerely yours, Superintendent

14 notes

·

View notes

Text

Section IV: The Evidences (Historical)

What is a tool and what is the nature of technology? Tools and technology are ideas, crafted to our physical world, that allow us a better grasp of completing tasks. Several trees may be of little use to someone, but once cut down, sawed into planks, and built into a house, they provide a use. It may take 5 days to fashion a tool with hand-power, out of local raw materials, but it would only take 1 day to fashion that tool if other tools were available, and you could fashion 500 of those tools in a day if you had a manufacturing plant. The amount of labor required to produce the same desired result is lowered with the aid of tools and technology. Productivity increases. To quote Nicholas Barbon, “The Use of Things, are to supply the Wants and Necessities of Man: There are Two General Wants that Mankind is born with; the Wants of the Body, and the Wants of the Mind...” [1] Not only does the usage of tools aid in production, but so does specialization of labor. If one person labors on one specific stage of a product, then that person will become proficient at it. Not only that, but there will not be the wasted time between the stages that often occurs. With one person proficient at each stage of making a product, with the aid of tools and technology, their productivity will significantly rise. There are some who doubt this, or hold skepticism towards productivity as an aim, but I hope to prove beyond a doubt that the usage of tools and technology are in fact helpful towards lowering labor required to produce items that service our needs.

In 1683, Matthew Hale described the conditions of individuals working in workshops that were set up to provide labor for the unemployed. In the mid-1600’s, 14 people working together in a mill could produce 32 yards of cloth in three weeks. These people would be divided into three weavers and spoolers, two breakers, six spinners, one fuller and burler, one sheer-man, one parter and picker. The first 32 yards would take two months, though, in a matter of becoming accustomed to machinery and the type of labor. Given that they work all year round, this would result in 17 32-yard rolls of cloth, or a total of 544 yards a year. This would amount to approximately 39 yards of cloth per person per year. [2] The amount of cloth that could be produced by a single person without the aid of specialization, or without the aid of tools, but just raw cotton, is a dismal estimation.

Nicholas Barbon describes the use of specialization and technology as it applies to economic fluctuations in the 1600’s...

The Use of Trade is to make, and provide things Necessary: Or useful for the Support, Defence, Ease, Pleasure, and Pomp of Life: Thus the Brewers, Bakers, Butchers, Poulterers, Cocks, with the Apothecaries, Surgeons, and their Dependencies provide Food, and Medicine for the support of Life: the Cutlers, Gun-smiths, Powder- makers, with their Company of Traders, make things for Defence; The Shoo-makers Sadlers, Couch, and Chair-makers, with abundance more for the Ease of Life: The Perfumers, Fidlers, Painters, and Booksellers, and all those Trades that make things to gratifie the Sense, or delight the Mind, promote Pleasure: But those Trades that are imploy’d to express the Pomp of Life, are Infinite; for, besides those that adorn Mans Body, as the Glover, Hosier, Hatter, Semstriss, Taylor, and many more, with those that make the Materials to Deck it; as Clothier, Silk-Weaver, Lace-Maker, Ribbon-Weaver, with their Assistance of Drapers, Mercers, and Milliners, and a Thousand more: Those Trades that make the Equipage for Servants, Trappings for Horses; and those that Build, Furnish, and Adorn Houses, are innumerable. [3]

In 1690, William Petty wrote, “...one Man by Art may do as much work, as many without it; viz, one Man with a Mill can grind as much Corn, as twenty can pound in a Mortar; one Printer can make as many Copies, as an Hundred Men can write by hand...” [4] and elsewhere he has written, “...a Windmill may he set up, and hy its heing moist and vaporous, there is always wind stirring over it, by which advantage the labor of many thousand Hands is saved, forasmuch as a Mill made by one Man in half a year, will do as much Labor, as four Men for Five Years together.” [5] Of the combination of men, he has written, “Those who have the command of the Sea Trade, may Work at easier Freight with more profit, than others at greater: for as Cloth must be cheaper made, when one Cards, another Spins, another Weaves, another Draws, an- other Dresses, another Presses and Packs; than when all the Operations above-mentioned, were clumsily performed by the same hand...” [6] Of those who are not among the society of men, he has written, “...those who live in Solitary places, must be their own Soldiers, Divines, Physicians, and Lawyers; and must have their Houses stored with necessary Provisions (like a Ship going upon a long Voyage,) to the great wast, and needless expence of such Provisions.” [7] In the 1700’s, David Hume wrote...

When a nation abounds in manufactures and mechanic arts, the proprietors of land, as well as the farmers, study agriculture as a science, and redouble their industry and attention. The superfluity, which arises from their labour, is not lost; but is exchanged with manufactures for those commodities, which men’s luxury now makes them covet. By this means, land furnishes a great deal more of the necessaries of life, than what suffices for those who cultivate it. [8]

Also in the 1700’s, Thomas Paine wrote, “...the natural state is without those advantages which flow from agriculture, arts, science and manufactures.” [9] In 1767, James Steuart wrote the book “An Inquiry into the Principles of Political Economy,” of which he gave countless examples of the usage of technology aiding production. With the use of technology, he has written, “I now suppose man to add his labour and industry to the natural activity of the soil: so far, as by this he produces an additional quantity of food, so far he lays a foundation for the maintenance of an additional number.” [10] — “...this [farming] will prove a more certain and more extensive fund of subsistence, than the precarious productions of spontaneous fruits, which cannot be increased at discretion, and in proportion to demand...” [11] — “Another advantage of cities is, the necessity arising from thence of having great roads, and these again prove a considerable encouragement to agriculture.” [12] — “...the making of roads and navigable canals must advance population, as they contribute to the advancement of agriculture.” [13] In general, on the theory of using technology to aid production, he has said, “Is it not plain, that when the earth is not improved, it cannot produce so much nourishment for man as when it is?” [14] and, “...the necessity of introducing every method of abridging labour and expence, in order to supply the wants of luxurious mankind, is absolutely indispensable, according to modern policy, according to experience, and according to reason.” [15] Pointing out a specific example of this policy, he writes, “...by using the spade and rake, instead of the plough and harrow, the lands of our island might be brought to produce with more abundance...” [16] On the hypothetical example that society was not allowed to use technology or tools, he writes, “Were the earth therefore uncultivated, the numbers of mankind would not exceed the proportion of the spontaneous fruits which she offers for their immediate use, or for that of the animals which might be the proper nourishment of man.” [17]

In 1815, Thomas Malthus wrote, “There is no person in the least acquainted with political economy, but must be aware that the advantages resulting from the division of labour, as applicable to nations as well as individuals, depend solely and entirely on the power of exchanging subsequently the products of labour.” [18] and elsewhere, “...if merely the best modes of cultivation, now in use in some parts of Great Britain, were generally extended, and the whole country was brought to a level, in proportion to its natural advantages of soil and situation, by the further accumulation and more equable distribution of capital and skill; the quantity of additional produce would be immense, and would afford the means of subsistence to a very great increase of population.” [19]

Also in the year 1815, Jean-Charles-Leonard Simonde de Sismondi wrote, “Thus men, combined in society, produced more than if each had laboured separately; and they preserve better what they have produced, because they feel the value of it better.” [20] Speaking of mankind, he wrote, “It invents machines, in which the wind, the fall of water, the expansion of steam, are substituted for the power of limbs...” [21] Of society, he writes, “All men are mutually necessary to each other.” [22] Specifically citing one example, he says, “The invention of the stocking frame, by means of which one man does as much work as a hundred did before, was a benefit for humanity, only because, at the same time, the progress of civilization, of population, and of wealth, increased the number of consumers.” [23] In a bit of a lengthier passage, he wrote...

Exchange first arose from superabundance: “Give me that article, which is of no service to you, and would be useful to me,” said one of the contacting parties, “and I will give you this in return, which is of no service to me, and would be useful to you.” Present utility was not, however, the sole measure of things exchanged. Each estimated for himself the selling price, or the trouble and time bestowed in the production of his own commodity, and compared it with the buying price, or the trouble and time necessary for procuring the required commodity by his own efforts; and no exchange could take place till the two contacting parties, on calculating the matter, had each discovered that it was better thus to procure the commodity wanted than to make it for himself. This accidental advantage soon pointed out to both a constant source of advantage in trading, whenever the one offered an article which he excelled in making, for an article which the other excelled in making; for each excelled in what he made often, each was unskillful and slow at what he made but seldom. Now, the more exclusively they devoted themselves to one kind of work, the more dexterity did they acquire in it, the more effectually did they succeed in rendering it easy and expeditious. This observation produced the division of trades; the husbandman quickly perceived, that he could not make as many agricultural tools by himself, in a month, as the blacksmith would make for him in a day. The same principle which at first separated the trades of the husbandman, shepherd, smith, and weaver, continued to separate those trades into an indefinite number of departments. Each felt that, by simplifying the operation committed to him, he would perform it in a manner still more speedy and perfect. The weaver renounced the business of spinning and dyeing; the spinning of hemp, cotton, wool, and silk, became each separate employment; weavers were still farther subdivided, according to the fabric and the destination of their stuffs; and at every subdivision, each workman, directing his attention to a single object, experienced an increase in his productive powers. In the interior of each manufactory, this division was again repeated, and still with the same success. Twenty workmen all laboured at the same thing, but each made it undergo a different operation: and the twenty workmen found that they had accomplished twenty times as much work as when each had laboured separately. [24] .... The increasing division of labour forms, as we have seen, the chief cause of increase in its productive powers; each makes better what he is constantly engaged in making, and when, at length, his whole labour is reduced to the simplest operation, he comes to perform it with such ease and rapidity, that the eye cannot make us comprehend how the address of man should arrive at such precision and promptitude. Often also this division leads to the discovery, that as the workman is now worth nothing more than a machine, a machine may in fact supply his place. [25] ... The application of science to art is not limited to the invention of machinery; its result is the discovery of raw materials, dyeing ingredients, preservative methods more sure and economical. It has produced better work at a cheaper rate; it has protected the health of labourers, as well as their produce; and its effect in augmenting wealth has almost always been beneficial to humanity. [26]

In 1825, Thomas Hodgskin, a staunch and valiant defender of the oppressed, would write, “By our increased skill and knowledge, labour is now probably ten times more productive than it was two hundred years ago...” [27] and “...since Mr Watt’s improvements on the steam engine one man can perform as much work with these instruments as ten men did before.” [28] In a lengthy section, he would write...

Fixed capital consists of the tools and instruments the labourer works with, the machinery he makes and guides, and the buildings he uses either to facilitate his exertions or to protect their produce. Unquestionably by using these instruments man adds wonderfully to his power. Without a hand saw, a portion of fixed capital, he could not cut a tree into planks; with such an instrument he could, though it would cost him many hours or days; but with a sawmill he could do it in a few minutes. Every man must admit that by means of instruments and machines the labourer can execute tasks he could not possibly perform without them; that he can perform a greater quantity of work in a given time, and that he can perform the work with greater nicety and accuracy than he could possibly do had he no instruments and machines. [29] [...] Whatever division of labour exists, and the further it is carried the more evident does this truth become, scarcely any individual completes of himself any species of produce. Almost any product of art and skill is the result of joint and combined labour. So dependent is man on man, and so much does this dependence increase as society advances, that hardly any labour of any single individual, however much it may contribute to the whole produce of society, is of the least value but as forming a part of the great social task. In the manufacture of a piece of cloth, the spinner, the weaver, the bleacher and the dyer are all different persons. All of them except the first is dependent for his supply of materials on him, and of what use would his thread be unless the others took it from him, and each performed that part of the task which is necessary to complete the cloth? [30]

In 1830, Nassau Senior would give a lecture to a university, in which he would state, “I was shown at Birmingham a small screw, which, in the manufacture of corkscrews, performed the work of fifty-nine men; with its assistance one man could cut a spiral groove in as many corkscrew shanks as sixty men could have cut in the same time with the tools previously in use.” [31] In a longer section, he would write...

I do not believe that there exists upon record a single instance in which the whole annual produce has been diminished by the use of inanimate machinery. Partly in consequence of the expense of constructing the greater part of machinery being defrayed out of profits or rent, and partly in consequence of the great proportion which the productive powers of machinery bear to the expense of its construction, its use is uniformly accompanied by an enormous increase of production. The annual consumption of cotton wool in this country, before the introduction of the spinning jenny, did not amount to 100,000 lbs.; it now amounts to 190,000,000. Since the power-loom came into use, the quantity of cotton cloth manufactured for home consumption has increased from 227,000,000 of yards (the average annual amount between the years 1816 and 1820), to 400,000,000 of yards (the annual average from 1824 to 1828 (Huskisson’s Speech, 1830). The number of copies of books extant at any one period before the invention .of the printing-press, was probably smaller than that which is now produced in a single day. [32]

The 1800’s marked the greatest development that political economy would receive. It would be the same century that the philosophy of Karl Marx would rise. In one of his pamphlets, in 1847, he would write...

In the process of production, human beings work not only upon nature, but also upon one another. They produce only by working together in a specified manner and reciprocally exchanging their activities. In order to produce, they enter into definite connections and relations to one another, and only within these social connections and relations does their influence upon nature operate — i.e., does production take place. [33]

It would be in the year 1848 that Marx would write the magnificent “Manifesto of the Communist Party.” In it, he would write...

The bourgeoisie, during its rule of scarce one hundred years, has created more massive and more colossal productive forces than have all preceding generations together. Subjection of nature’s forces to man, machinery, application of chemistry to industry and agriculture, steam navigation, railways, electric telegraphs, clearing of whole continents for cultivation, canalization or rivers, whole populations conjured out of the ground — what earlier century had even a presentiment that such productive forces slumbered in the lap of social labor? [34]

A partner in many of Marx’s works, Friedrich Engels would offer his contribution to the idea of political economy. In 1876, he would write...

Mastery over nature began with the development of the hand, with labour, and widened man’s horizon at every new advance. He was continually discovering new, hitherto unknown properties in natural objects. On the other hand, the development of labour necessarily helped to bring the members of society closer together by increasing cases of mutual support and joint activity, and by making clear the advantage of this joint activity to each individual. [35]

In 1899, Thorsten Veblen would discuss the rise of civilization, writing, “With the use of tools the possibility of his acquiring a different disposition gradually began, but even then the circumstances favoring the growth of a contentious disposition supervened only gradually and partially.” [36] In 1902, John McDowell would write an article discussing the life of a miner. In it, he that a miner could procure twelve to fifteen tons of coal, each day, with the aid of modernized equipment. [37] In 1910, a collection of articles by Henry Demarest Lloyd would be published (seven years after his death) in a book entitled, “The Lords of Industry.” In it, he wrote, “Though coal is an article of commerce greater in volume than any other natural product in the United States carried on railroads, amounting to not less than 330,000,000 tons a year; and though the appliances for its transportation have been improved and the cost cheapened every year, so that it can be handled with less cost and risk than almost any other class of freight...” [38] In 1930, L.F. Giblin would deliver an inaugural speech in Australia, saying...

The economist tells him that his real wages are six times what his father had in England a hundred years ago. The economist may further tell him that this has been made possible, not by his combined bargaining power, but by the increased productivity of industry through advances of knowledge and technique, and that he is getting only the same proportionate share of production as a hundred years ago.... [the] hydro-electric plant [to the]...bush saw-mill. [39]

The authors of the past, covering all centuries, have universally confirmed the efficiency of technology and tools in accomplishing labor. By using a pickaxe instead of bare hands, or a rock, a person will more effectively mine coal, and by using great, massive machines instead of a pickaxe, a person will mine coal even more effectively. The same analogy can be compared to any other field: agriculture, manufacturing, among all other industries. While it is confirmed by a great deal of authors of the past, the question of the efficiency of machinery and technology, of all forms that it make take, in our modern world, is still unanswered. It is in the next section that I hope to answer this question.

#capitalism#civilization#class#class struggle#communism#consumption#economics#industrial society#poverty#workers#anarchism#anarchy#anarchist society#practical anarchy#practical anarchism#resistance#autonomy#revolution#anti capitalist#anti capitalism#late stage capitalism#daily posts#libraries#leftism#social issues#anarchy works#anarchist library#survival#freedom

3 notes

·

View notes

Text

since I haven’t worked on it in ages, here’s a basic ah desc of my three spec bio worlds so far because e (low quality lol)